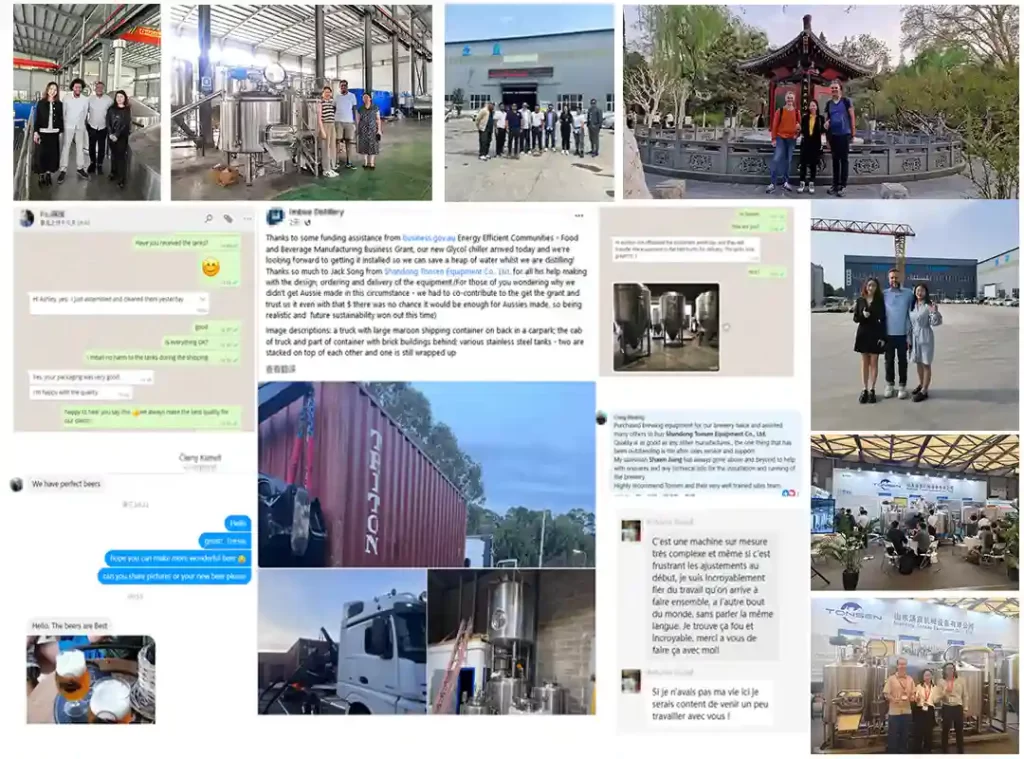

Tonsen is an outstanding beer equipment manufacturer in China and is

highly praised by customers from many countries around the world for its

customized services.

Step 1: Tea Brewing

The process begins with the selection of tea, with common varieties including black, green, white, oolong, and blended teas. Each type of tea provides different levels of tannins, antioxidants, and flavor compounds, which directly affect the taste of kombucha. Whole-leaf teas release tannins and other compounds more slowly, while processed tea bags, with their larger surface area, release caffeine more quickly.

Step 2: Tea Dilution

The brewed tea is usually highly concentrated and at a higher temperature, so it needs to be mixed with brewing water at room temperature in a specific ratio. This helps cool the tea and facilitates subsequent fermentation while also reducing the concentration and increasing the yield.

Step 3: Primary Fermentation

The diluted tea is transferred to the first-stage fermenter for fermentation. This stage typically takes place in an open, flat-top, atmospheric pressure fermentation tank with a large diameter and low height for easy operation. The fermentation temperature is usually between 22–28°C, and the process lasts for approximately seven days.

Step 4: Secondary Fermentation

After the primary fermentation is complete, the tea is transferred to a closed secondary fermentation vessel. During this stage, juice or puree is often added to the tea to enhance its flavor. The fermentation temperature is generally maintained around 15°C, and the process lasts for another seven days.

Step 5: Filtration

Once the secondary fermentation is complete, the tea undergoes a final filtration process to remove particulate impurities. Common filtration methods include kieselguhr filtration and multi-tier fine membrane filtration (10 microns, 5 microns, and 0.5 microns).

Step 6: Brite Tank

The brite tank is used to mix flavorings, initiate secondary fermentation, and carbonate the kombucha before packaging and distribution.

Step 7: Filling

The filling process requires careful temperature control to slow down fermentation and prevent over-carbonation or bottle explosions. The filling machines are equipped with sensors that monitor and adjust filling speed and pressure, allowing for adaptation based on the fermentation stage and ensuring consistency in carbonation levels. These machines are made from corrosion-resistant materials to withstand kombucha’s acidity and are designed with minimal areas for residue accumulation, ensuring cleanliness and safety.

The main body of this brewhouse system is composed by five systems: brewhouse system, fermentation system, cooling system, CIP system and control system. Details: Mash/ Boiling tun and Lauter/ Whirlpool tan, auxiliary machine includes plate he…

Tonsen’s 50HL Industry Brewery Equipment: scalable, energy-efficient, advanced brewing for industrial breweries. Elevate production today!

The main body of this brewhouse system is composed by five systems: brewhouse system, fermentation system, cooling system, CIP system and control system. Details: Mash/ Boiling tun and Lauter/ Whirlpool tan, auxiliary machine includes plate he…

The 4000L beer brewing equipment offers substantial benefits for large-scale breweries. With its high capacity, it enables efficient production to meet significant demand. Economies of scale result in lower production costs per unit, enhancing pro…

The 4000L beer brewing equipment offers substantial benefits for large-scale breweries. With its high capacity, it enables efficient production to meet significant demand. Economies of scale result in lower production costs per unit, enhancing pro…

2000L Beer Brewing Equipment is designed for brewing craft beer with commercial purposes for Craft brewery, microbrewery, brewpub, taproom and restaurant.Brewer friendly design, the brewers will find it easy to brew an outstanding full-types beer …

2000L beer brewing equipment can be applied to various fields, including beer houses, small breweries, small commercial brewing businesses,This multi-container brewing system has extremely high capacity flexibility.Tonsen plans and designs complet…

2000L beer brewing equipment can be applied to various fields, including beer houses, small breweries, small commercial brewing businesses,This multi-container brewing system has extremely high capacity flexibility.Tonsen plans and designs complet…

The 1500L beer brewing equipment offers cost-effective production with moderate capacity, suitable for small to medium-sized breweries. Its versatility allows for brewing various beer styles, meeting diverse market demands. The compact size is ide…

The 1500L beer brewing equipment offers cost-effective production with moderate capacity, suitable for small to medium-sized breweries. Its versatility allows for brewing various beer styles, meeting diverse market demands. The compact size is ide…

loading…

已经是到最后一篇内容了!

This website uses cookies to improve your browsing experience. By continuing to use this site, you accept the use of our cookies. Data collected from this website is processed and stored in the United States.