The Beer Brewing Process: An In-Depth Look at Brewery Equipment

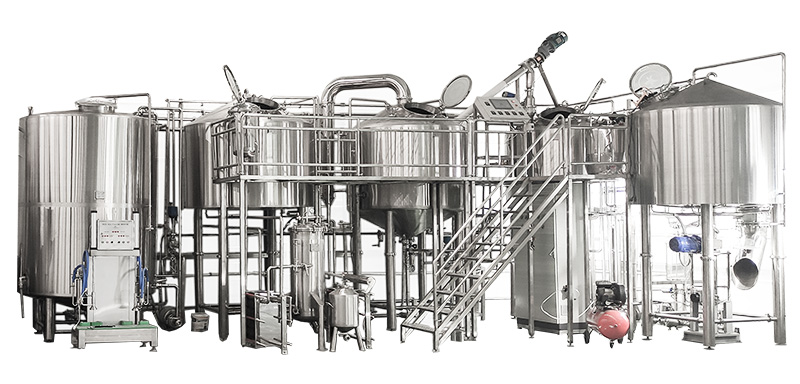

Brewing beer is both an art and a science, involving a series of precise steps that transform raw ingredients into the beloved beverage enjoyed by millions around the world. Understanding the brewing process and the essential brewery equipment involved can provide deeper insights into how beer is made and the craftsmanship behind each batch. This article will walk you through the brewing process, emphasizing the functions of critical equipment such as the mash tun, fermentation tank, bright tank, and CIP (Clean-In-Place) system.

The Brewing Process Overview

The brewing process can be broken down into several key stages: mashing, boiling, fermentation, conditioning, and packaging. Each of these stages requires specific brewery equipment to ensure optimal results. Let’s explore each step in detail.

1. Mashing: The Mash Tun

The journey of brewing begins in the mash tun, a specialized vessel where the starches from malted grains are converted into fermentable sugars. Here’s how it works:

- Ingredients: The primary ingredients for mashing are malted grains (often barley), water, and sometimes adjuncts like corn or rice.

- Process: The malted grains are crushed into a coarse powder known as grist. This grist is mixed with hot water in the mash tun at a controlled temperature, typically between 148°F and 158°F (64°C to 70°C). The heat activates enzymes in the malt, which convert starches into sugars. This process can take anywhere from 30 minutes to several hours, depending on the desired beer style.

- Outcomes: The result of mashing is a sugary liquid called wort, which will be boiled and fermented. The quality of the wort significantly impacts the flavor, aroma, and alcohol content of the final beer.

2. Lautering

After mashing, the wort must be separated from the solid grain husks. This process occurs in the lautering vessel, though some brewhouses combine the mash tun and lauter tun into a single piece of equipment.

- Function: The wort is drained from the mash tun, and additional hot water is sprayed over the grain bed to extract as much sugar as possible. This is known as sparging.

- Result: The collected wort is transferred to the boiling kettle, while the spent grains are typically removed for use in animal feed or other purposes.

3. Boiling: The Brew Kettle

The next stage is boiling, which occurs in the brew kettle. This step is crucial for several reasons:

- Sterilization: Boiling the wort sterilizes it, killing any unwanted bacteria or wild yeast that could spoil the beer.

- Hops Addition: Hops are added during this phase, which contributes bitterness, flavor, and aroma to the beer. Different hop varieties can produce distinct flavor profiles.

- Duration and Temperature: The wort is typically boiled for 60 to 90 minutes. The timing of hop additions during the boil influences the final beer’s taste and aroma.

- Cooling: After boiling, the wort must be rapidly cooled to a temperature suitable for fermentation, usually between 65°F and 75°F (18°C to 24°C) for ales and 45°F to 55°F (7°C to 13°C) for lagers. This is often done using a heat exchanger.

4. Whirlpooling:The Whirlpool Sedimentation

Whirlpooling is designed to separate solid particles, such as hop residues and trub (protein coagulates formed during boiling), from the liquid wort. These solids, if not removed, could negatively affect the clarity and flavor stability of the final beer.

● Duration:The whirlpool process typically lasts around 15 to 30 minutes, allowing the solids enough time to settle.

● Outcome:The clarified wort is then drained from the tank, leaving the solids behind. This clarified wort is cooled

and sent to fermentation tanks, where yeast is added to begin the fermentation process.

● Benefits:Improved wort clarity;Enhanced beer quality and flavor stability;Efficient removal of undesired solids

without mechanical filtration.

5. Fermentation: The Fermentation Tank

Once the wort is cooled, it is transferred to a fermentation tank, where yeast is added to initiate the fermentation process.s

- Yeast Addition: Yeast consumes the sugars in the wort, producing alcohol and carbon dioxide as byproducts. This stage can last from several days to several weeks, depending on the beer style and yeast strain used.

- Tank Design: Fermentation tanks are typically made of stainless steel, which provides durability and ease of cleaning. They often have temperature control jackets to maintain optimal fermentation conditions.

- Monitoring: During fermentation, brewers closely monitor specific gravity (sugar concentration), temperature, and other parameters to ensure the yeast is performing as expected.

6. Conditioning: The Bright Tank

After fermentation, the beer needs to be conditioned to develop its flavors and clarity. This usually occurs in a bright tank.

- Function: Bright tanks are used for additional maturation and clarification of the beer. They allow any remaining yeast and particulates to settle out, resulting in a clearer final product.

- Carbonation: This stage also allows for natural carbonation, as carbon dioxide produced during fermentation is retained. Some brewers may also add priming sugar or carbon dioxide to achieve desired carbonation levels.

- Temperature Control: Bright tanks often have temperature control systems to facilitate cold conditioning, which can enhance the beer’s flavors and aromas.

7. Packaging

Once conditioning is complete, the beer is ready for packaging. This step involves transferring the beer into kegs, bottles, or cans for distribution.

- Packaging Equipment: Automated packaging lines are often used to fill kegs and bottles efficiently. Properly designed systems minimize oxygen exposure, preserving the beer’s freshness.

- Quality Control: Throughout the packaging process, quality control measures are critical to ensure that the beer meets desired specifications before reaching consumers.

The Importance of CIP Systems

Maintaining cleanliness and sanitation in the brewing process is vital for producing high-quality beer. This is where a CIP (Clean-In-Place) system comes into play.

1. Automation of Cleaning

CIP systems automate the cleaning process for brewery equipment, ensuring that tanks, pipes, and other components are thoroughly sanitized without requiring disassembly.

- Chemicals and Solutions: The CIP process typically involves circulating hot water and cleaning solutions through the equipment to remove residues and contaminants.

- Efficiency: By automating cleaning, brewers can save time and labor costs while ensuring that their equipment remains in optimal condition for brewing.

2. Consistency and Safety

CIP systems help maintain a consistent level of cleanliness, reducing the risk of contamination and ensuring that every batch of beer meets quality standards.

- Regulatory Compliance: Many brewing facilities must adhere to health and safety regulations. A well-designed CIP system aids compliance by ensuring proper sanitation practices.

Conclusion

Brewing beer is a multifaceted process that relies heavily on specialized brewery equipment at each stage. From the mash tun, where sugars are extracted from grains, to the fermentation tank, where yeast transforms wort into beer, each piece of equipment plays a critical role in ensuring quality and consistency.

Investing in high-quality brewery equipment and maintaining it through efficient CIP systems is essential for any brewing operation. Understanding the functions and importance of each component allows brewers to create exceptional beers that stand out in a competitive market. With careful attention to detail and a commitment to quality, brewers can continue to craft the beloved beverage enjoyed around the globe.

https://www.tcbrewbeer.com/en/4000l-bright-tank/

https://www.tcbrewbeer.com/en/category/product/brewery-equipment/

Related recommendations

How to Master Brewery Planning: Calculate the Ideal Brewery Size for Your Craft Beer Business

215Learn how to calculate the ideal brewery size for your craft beer business with expert tips on brewery planning, equipment space, and efficient layouts.

View detailsFermentation Control: Best Practices for Consistent Beer Quality

241Ensure consistent beer quality with the right fermentation tank and fermentation system for optimal brewing results.

View detailsBrewing New Beginnings with Professional Brewing Equipment

480Elevate your brewing with professional brewing equipment. Discover innovative, sustainable solutions to craft exceptional beer in 2025.

View detailsStarting a Brewery Business Plan: Your Ultimate Guide to Crafting Success

211Starting a brewery business plan

View details

Shandong Tonsenbrew Co., Ltd.

Shandong Tonsenbrew Co., Ltd.

HelloPlease log in